To create a perfect, smooth water sheet over a weir, guarantee the weir length matches your flow needs—longer crests increase capacity but must be balanced with downstream conditions. Control the flow rate to keep it steady; too much speed causes turbulence and imperfections. Adjust the head height to provide enough energy without causing excessive splashing. Optimizing these factors leads to a stable, glass-like sheet, and continued details will help refine your design skills further.

Key Takeaways

- Longer weirs increase flow capacity but must be balanced to prevent turbulence and upstream flooding.

- Adequate head height boosts flow efficiency without causing excessive turbulence or energy loss.

- Maintaining a steady, controlled flow rate ensures a uniform, glass-like water sheet without ripples or tears.

- Proper crest shape and downstream conditions promote smooth, stable flow and prevent irregularities.

- Regular inspection and precise design optimize weir length and flow, achieving a perfect, seamless water sheet.

Understanding the Basics of Weirs and Flow Dynamics

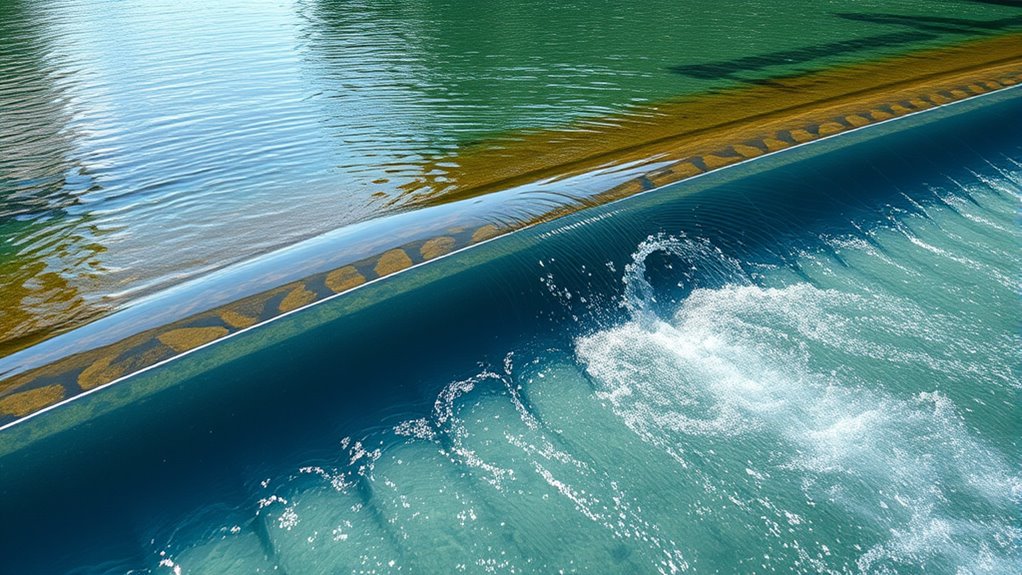

Understanding the basics of weirs and flow dynamics is essential for grasping how water moves through open channels. Weirs are barriers placed across streams or canals to control water levels and measure flow rates. When water flows over a weir, it accelerates and creates a predictable, free-flowing jet. The height of the water upstream, called the head, determines the flow rate over the weir. Flow dynamics involve understanding how water responds to obstacles, pressure, and gravity. As water approaches a weir, it gains speed and depth, influencing discharge. Recognizing these principles helps you predict how changes to a weir’s shape or height will impact flow. Mastering flow behavior around weirs enables better management of water resources and precise flow measurement. Modern flow management also benefits from noise levels considerations, ensuring systems operate quietly and efficiently.

The Relationship Between Weir Length and Water Discharge

The length of a weir directly influences the volume of water it can discharge. A longer weir provides a larger surface area for water to flow over, increasing the potential flow rate. When water approaches the weir, it accelerates as it passes the crest, and a longer crest allows more water to pass simultaneously. This means that, all else being equal, extending the weir length boosts the total discharge capacity. However, this relationship isn’t linear indefinitely; factors like flow velocity and downstream conditions also matter. If the weir is too short, it restricts flow, causing upstream buildup and potential overflow. Proper design considerations, such as weir efficiency, are essential for ensuring optimal performance. Thus, selecting the appropriate length guarantees efficient discharge, balancing capacity with flow stability and preventing unnecessary overflow or underperformance.

How Flow Rate Influences Sheet Formation

When the flow rate increases, you’ll notice the sheets become thinner and more uniform. Controlling the flow rate helps you manage the sheet width effectively. However, too much flow can lead to imperfections and reduce the quality of the formation. Additionally, understanding the trustworthiness of AI models can help in developing better control systems for sheet production.

Increased Flow, Thinner Sheets

As flow rate increases, the sheets formed become noticeably thinner because more liquid moves through the weir in a shorter amount of time. When you push more flow, the liquid spreads out quickly, reducing the thickness of each sheet. This happens because the available surface area for the liquid to spread over remains constant, but the volume passing through rises sharply. The faster flow prevents the liquid from accumulating into thicker layers, resulting in a finer, more delicate sheet. You’ll notice that with higher flow rates, the sheet’s uniformity can improve, but managing its thickness becomes more critical. Understanding this relationship helps you control sheet quality, ensuring the liquid doesn’t become too thin or fragile for your specific application. Additionally, controlling flow rate is essential for maintaining consistency in sheet formation, which directly impacts the final product quality.

Flow Rate Controls Sheet Width

Have you ever wondered how increasing the flow rate can directly influence the width of the sheet you’re forming? When you raise the flow rate, you deliver more material over a shorter time, causing the sheet to spread wider. A higher flow rate pushes the material further across the surface, resulting in a broader sheet. This relationship allows you to control sheet width precisely by adjusting flow rates to match your desired specifications.

- Feel the power of control as flow adjustments shape your sheet’s size

- Experience the confidence that comes with predictable, consistent widths

- Witness how small changes can produce big differences in sheet dimensions

- Gain mastery over your process, ensuring perfect, uniform sheets every time

Excess Flow Causes Imperfections

Increasing the flow rate beyond ideal levels can lead to noticeable imperfections in the sheet. When you push too much fluid through the weir, the excess causes turbulence and uneven flow distribution. This turbulence disrupts the smooth formation of the sheet, creating ripples, thin spots, or even tears. Higher flow rates also increase the likelihood of air entrainment, which weakens the sheet’s integrity. You might notice surface irregularities or inconsistent thickness, reducing the quality of the final product. To maintain a perfect sheet, you need to control flow carefully, ensuring it stays within *efficient* limits. Too much flow overwhelms the system, while too little hampers production. Striking the right balance is essential for smooth, uniform sheet formation without imperfections. Proper flow regulation is also critical to prevent clutter buildup that can interfere with the process.

Optimal Weir Length for Smooth Water Sheets

Choosing the most suitable weir length is essential for producing smooth, stable water sheets. A well-chosen length ensures your flow remains even and controlled, avoiding turbulence and disruptions. To achieve this, focus on the balance between length and flow rate, adjusting until the water glides effortlessly over the weir. The right length can turn a chaotic cascade into a mesmerizing, flawless sheet that captivates viewers. When you get it right, you’ll see the water stretch out cleanly and consistently, creating a sense of harmony and perfection. Remember, the goal is stability and smoothness, not just volume. With the correct weir length, you’ll unseal the true beauty of your water flow, transforming it into a captivating display of precision and grace. Achieving optimal flow control involves understanding how the weir length influences water behavior and making adjustments accordingly.

The Impact of Head Height on Flow Efficiency

Your flow efficiency depends heavily on head height, which directly influences water speed over the weir. As elevation increases, the water accelerates, improving flow but also risking turbulence. Understanding how head height impacts flow helps you optimize weir design for better performance.

Head Height and Speed

How does head height influence flow efficiency in weirs? When the head height increases, water accelerates faster, boosting flow speed. This creates a more dynamic and powerful sheet, making your system more effective. But, too high a head can cause turbulence, reducing flow stability and risking overflow. The key is finding that perfect balance where flow is swift yet controlled. Properly managing natural materials and ensuring good lighting can further optimize flow conditions. Feel the thrill of harnessing water’s energy to optimize your weir. With the right head height:

- You release maximum flow potential

- You prevent turbulence and overflow

- You gain control over water movement

- You create a smoother, more reliable sheet

Elevation’s Effect on Flow

Elevation, or head height, plays a crucial role in determining flow efficiency in weirs. The higher the elevation above the crest, the greater the potential energy driving water over the weir. As head height increases, flow rate typically accelerates, allowing more water to pass through in less time. However, this relationship isn’t linear; beyond a certain point, increased elevation can cause turbulence and energy losses, reducing flow efficiency. You need to contemplate the balance between sufficient head height for desired flow and avoiding excess that leads to spillover or erosion. Properly managing elevation ensures consistent, smooth flow, optimizing the weir’s performance. By understanding how head height impacts flow, you can design and operate weirs that maximize efficiency while minimizing turbulence and wear.

Calculating the Ideal Flow Conditions for a Perfect Sheet

To achieve a perfect sheet, you need to determine the ideal flow conditions that promote smooth, uniform water distribution across the weir. Focus on maintaining a steady, controlled flow rate that matches the weir’s design. Too fast, and the water will splatter; too slow, and it won’t form a continuous sheet. Use precise calculations based on flow velocity, volume, and the weir’s dimensions. This balance ensures the water spreads evenly without turbulence or gaps. Proper flow management is essential for consistent results.

- Feel the satisfaction of a seamless, glass-like water sheet.

- Experience confidence knowing your flow is perfectly calibrated.

- Witness the beauty of flawless, uniform distribution.

- Enjoy the mastery of controlling water with precision.

Common Factors That Disrupt Water Flow Over a Weir

Even with carefully calibrated flow conditions, certain factors can still cause disruptions in the water’s smooth passage over a weir. Sediment buildup is a common issue, as particles can clog the crest and alter flow patterns. Vegetation or debris lodged near the weir can also cause turbulence, creating uneven flow and reducing efficiency. Structural irregularities, such as cracks or rough surfaces, disturb the laminar flow, leading to unpredictable water behavior. Additionally, fluctuations in water volume or sudden inflows can create turbulence that breaks the steady sheet. These factors compromise the precision of flow measurement and weir performance. To maintain ideal flow, regular inspection and maintenance are essential to clear obstructions and address structural imperfections promptly.

Practical Tips for Designing Effective Weirs

Designing effective weirs requires careful consideration of several key factors to guarantee accurate flow measurement and ideal performance. First, confirm the crest length matches your flow needs; too short or too long can lead to measurement errors. Second, select the right crest shape—sharp crests promote consistent flow, while broad crests reduce turbulence. Third, pay attention to downstream conditions; smooth, unobstructed flow ensures reliable readings. Fourth, consider construction quality—use durable materials and precise installation to prevent distortions. Additionally, understanding regional divorce statistics can help anticipate potential challenges in legal processes related to water rights and property disputes. Finally, consider construction quality—use durable materials and precise installation to prevent distortions.

Real-World Examples of Achieving the Perfect Water Sheet

Achieving the perfect water sheet over a weir in real-world applications depends on meticulous attention to details like crest length, shape, and downstream conditions. For example, in hydroelectric plants, engineers carefully design the crest to ensure a smooth, uniform flow, preventing air entrainment or splashing. Similarly, fish ladders incorporate specific crest shapes to maintain a consistent sheet that guides aquatic life without turbulence. In flood control structures, adjusting downstream slopes and crest dimensions helps stabilize flow, creating a clean, predictable sheet. These examples show that success hinges on balancing crest length, shape, and downstream environment. When you pay close attention to these factors, you optimize flow conditions, producing a stable, aesthetically pleasing water sheet that functions efficiently and reliably. Cruise FAQs

Frequently Asked Questions

How Does Air Entrainment Affect Water Sheet Stability?

Air entrainment can destabilize your water sheet by creating bubbles and turbulence, which disrupt smooth flow. When air gets trapped, it weakens the sheet’s cohesion, making it more prone to breaking apart or forming irregular patterns. To maintain stability, you should control factors like flow rate and surface tension, minimizing air entrainment and ensuring a consistent, stable sheet for your application.

Can Varying Water Temperature Change Flow Characteristics?

Imagine a flowing water sheet shimmering under sunlight—when water temperature varies, so do its flow characteristics. Warmer water becomes more viscous, moving smoothly and spreading wider, like silk gliding effortlessly. Cooler water thickens, reducing flow speed and causing ripples or uneven sheets. You’ll notice changes in splash, turbulence, and stability, as temperature shifts alter viscosity, affecting how the water behaves and interacts with the environment.

What Materials Are Best for Constructing Durable Weirs?

You should choose durable materials like concrete, steel, or high-quality plastics for constructing weirs. Concrete offers strength and longevity, especially when reinforced, making it ideal for large or permanent structures. Steel provides robustness and can withstand high flow rates, but may require protective coatings to prevent corrosion. High-grade plastics are lightweight, resistant to corrosion, and suitable for smaller or temporary weirs. Select based on your specific needs and environmental conditions for the best results.

How Environmental Factors Influence Weir Performance?

Environmental factors critically influence your weir’s performance. Changes in water temperature can affect flow rates and material durability, so you need to select materials that withstand temperature fluctuations. Sediment buildup can obstruct flow, requiring regular maintenance. Weather conditions like wind and rain impact how your weir operates, necessitating proper design adjustments. By monitoring these factors and adapting your setup accordingly, you guarantee consistent, reliable flow control and extend your weir’s lifespan.

Are There Automated Systems to Optimize Flow Over Weirs?

Yes, automated systems exist that optimize flow over weirs, acting like vigilant guardians guiding water smoothly. These systems use sensors and advanced algorithms to adjust gates and flows in real-time, ensuring ideal performance regardless of environmental changes. With these intelligent tools, you can maintain steady water levels, prevent flooding, and maximize efficiency effortlessly, turning a complex task into a symphony of precision and control.

Conclusion

By understanding how weir length and flow work together, you can craft a perfect water sheet every time. Keep an eye on flow rates, head height, and design details—these are the keys to smooth, consistent results. Remember, it’s not just about pushing water; it’s about making it dance exactly how you want. With a little know-how, you’ll have the flow under control and everything running like clockwork.