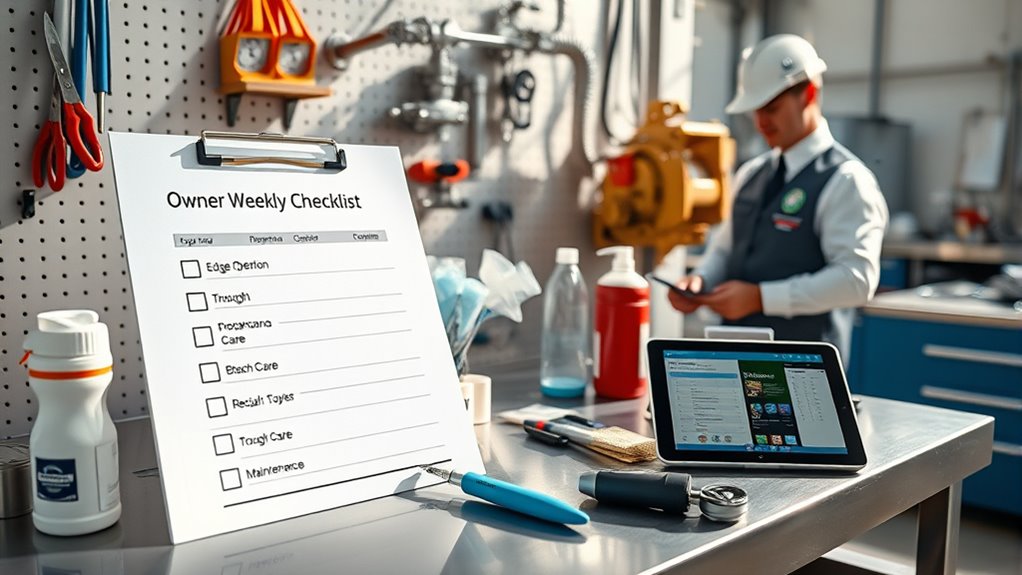

Each week, inspect your equipment for wear, damage, or leaks, and guarantee safety features work properly. Clean debris from edges and troughs, using gentle tools to avoid damage, and sanitize surfaces to prevent bacteria buildup. Check water flow levels, adjusting valves for even coverage, and replace any worn or damaged parts. Keep notes on maintenance activities and schedule upcoming tasks. For detailed tips to keep everything running smoothly, continue exploring this helpful guide.

Key Takeaways

- Conduct thorough equipment inspections, including checking for wear, damage, and safety features, and log findings regularly.

- Clean edges and troughs weekly, removing debris and algae, and sanitize high-touch surfaces with approved disinfectants.

- Monitor water flow for even distribution, adjusting control valves and checking pressure gauges as needed.

- Maintain organized inventory of supplies, replenish cleaning and safety materials, and plan ahead to prevent shortages.

- Schedule and confirm upcoming maintenance appointments, coordinate with service providers, and update maintenance timelines consistently.

Inspect Equipment Condition and Functionality

Regularly inspecting your equipment guarantees it stays in peak condition and prevents unexpected breakdowns. Each week, take time to examine all machinery and tools for signs of wear or damage. Check belts, blades, and moving parts for cracks, rust, or looseness. Test electrical connections and controls to ensure they respond correctly. Listen for unusual noises during operation, which could indicate underlying issues. Make sure safety features, like guards and emergency stops, are intact and functional. Address any minor problems immediately to avoid costly repairs later. Keeping a detailed inspection log helps track issues over time and plan maintenance. Staying proactive with equipment checks ensures your operations run smoothly, reduces downtime, and extends the lifespan of your tools. Being aware of dog breed characteristics can also help in choosing the right companion for your work environment, promoting safety and compatibility.

Clear and Clean Edges and Troughs

Keeping edges and troughs clear and clean is essential for maintaining efficient operations. Debris, algae, or buildup can obstruct water flow and cause equipment strain or malfunctions. Regularly inspect these areas for obstructions and remove any debris promptly. Use a soft brush or cloth to clean edges and troughs thoroughly, avoiding harsh chemicals that could damage surfaces. Make certain the troughs are free of any blockages that might cause water to overflow or stagnate. Pay attention to corners and joints where particles tend to accumulate. Keeping these areas clean helps prevent clogs and guarantees smooth operation. Incorporate this task into your weekly routine to maintain optimal performance and prolong equipment lifespan. Consistently maintaining proper cleaning techniques ensures that buildup does not compromise system efficiency. Clean edges and troughs regularly, and you’ll keep everything running smoothly.

Check and Adjust Water Flow Levels

To guarantee your system operates efficiently, you need to check and adjust water flow levels regularly. Proper flow ensures your edges stay clean and your troughs don’t overflow or dry out. First, observe the water distribution during operation to identify any uneven flow. Next, use your control valves or regulators to tweak the water volume. Make sure the flow isn’t too weak, which can cause dry spots, or too strong, risking erosion or overspray. Keep an eye on the pressure gauge if available, and compare it to manufacturer recommendations. Additionally, ensure that your water flow is consistent with proper water management practices for optimal system performance. Finally, run the system for a few minutes after adjustments to confirm the water flows evenly across all zones. Regularly monitoring and fine-tuning your water flow prevents issues and maintains optimal operation.

Examine and Replace Worn or Damaged Parts

After adjusting your water flow levels, it’s important to inspect the system for any worn or damaged parts. Look closely at hoses, fittings, and seals for cracks, leaks, or deterioration. Check the pump and filters for debris buildup or signs of wear. If you notice any rust, corrosion, or deformities, replace those components promptly. Worn or damaged parts can cause system inefficiency or failure, so don’t delay repairs. Keep a list of parts that need replacing and ensure you have spares on hand. Regularly maintaining these elements prevents costly breakdowns and keeps your operation running smoothly. Always follow manufacturer instructions when replacing parts to guarantee proper fit and function. Staying proactive now saves you time and trouble later. Cheating can sometimes lead to overlooked issues in systems where trust and accountability are crucial, so be vigilant in maintenance routines.

Sanitize and Disinfect Surfaces

Regularly sanitizing and disinfecting surfaces is essential to prevent the spread of germs and maintain a clean environment. You should focus on high-touch areas such as counters, handles, and equipment to guarantee they stay hygienic. Use approved disinfectants and follow the manufacturer’s instructions for proper use. Always wear gloves and ensure good ventilation during cleaning. Keep a schedule to make sure surfaces are cleaned at least once a week or more frequently if needed. Avoid cross-contamination by using different cleaning cloths for different areas. Properly dispose of used wipes and cleaning supplies after each use. Regular cleaning not only protects your health but also prolongs equipment life and maintains a professional appearance.

- Identify high-touch surfaces to prioritize cleaning

- Use appropriate disinfectants and follow instructions

- Wear gloves and ensure proper ventilation

- Dispose of cleaning materials responsibly

Review and Record Maintenance Activities

You should regularly review your maintenance logs to guarantee all activities are up to date. Recording completed tasks helps you stay organized and identify upcoming needs. Don’t forget to schedule your next checks to keep everything running smoothly. Incorporating sound healing techniques into your routine can also promote relaxation and overall well-being.

Track Maintenance Logs

Keeping detailed track maintenance logs is essential for guaranteeing your track stays in top condition. Regularly recording maintenance activities helps you identify patterns, spot recurring issues, and plan future tasks more effectively. When reviewing and recording, note the date, specific work performed, materials used, and any observations about track condition. This documentation provides a clear history of maintenance efforts, which can be useful for troubleshooting problems or verifying completed work. Consistent logs also help you stay organized and ensure no task is overlooked. By maintaining accurate records, you can track progress over time and make informed decisions about needed repairs or upgrades. Additionally, skin care routines, such as using eye patches, can complement your overall self-care and maintenance practices.

Schedule Next Checks

Scheduling your next track checks promptly after recording maintenance activities guarantees issues are addressed before they worsen. Consistent scheduling ensures you catch problems early, preventing costly repairs and downtime. Use your maintenance logs to determine when inspections are due and set reminders accordingly. To streamline this, create a simple schedule like the one below:

| Check Type | Frequency | Next Due Date |

|---|---|---|

| Track Alignment | Weekly | [Insert Date] |

| Lubrication Points | Every 2 Weeks | [Insert Date] |

| Track Surface Check | Monthly | [Insert Date] |

Staying organized with a clear schedule keeps your operation smooth and reliable. Regular cleaning and maintenance of equipment prevents buildup and ensures optimal performance. Keep records up to date and adjust as needed.

Prepare Supplies and Schedule Next Maintenance

Make certain you have all essential supplies stocked to keep your maintenance on track. Planning your maintenance timeline now helps you stay organized and avoid last-minute rushes. By preparing ahead, you ensure everything runs smoothly when it’s time for the next service. Additionally, reviewing your vendor reliability and service quality can help prevent unexpected service interruptions.

Stock Essential Items

To make certain your home runs smoothly, it’s essential to regularly stock up on key supplies and plan for upcoming maintenance. Keeping a well-stocked inventory ensures you’re prepared for routine issues and unexpected needs. Check your supplies regularly and replenish items before they run out. This proactive approach minimizes downtime and prevents emergencies. Focus on essential items that support your edge operation and trough care. Grocery savings strategies can also be applied to managing your maintenance supplies efficiently.

- Spare filters and replacement parts

- Cleaning supplies and tools

- Backup batteries and lighting

- Basic first-aid kit and safety gear

Having these essentials on hand keeps your maintenance routine efficient and stress-free. Remember to adjust your stock levels based on usage patterns and upcoming scheduled tasks. Staying organized with your supplies helps you keep your system in top shape all year round.

Plan Maintenance Timeline

Planning your maintenance timeline involves proactively preparing supplies and setting a schedule for upcoming tasks. Start by reviewing your last maintenance session to identify what supplies you’ll need and when the next check or service should occur. Create a detailed timetable that includes key dates for oil changes, filter replacements, and inspections. Having supplies ready in advance prevents delays and ensures smooth operations. Use a calendar or reminder system to alert you when maintenance is due, so you don’t forget important tasks. Regularly updating your timeline keeps you organized and helps catch issues early. Additionally, considering the diverse designs available for planters can inspire you to incorporate new aesthetic elements into your maintenance routine, ensuring your equipment and decor stay in harmony. By planning ahead, you minimize downtime and extend the lifespan of your equipment, making maintenance more efficient and less stressful.

Frequently Asked Questions

How Often Should Edge Operation and Trough Care Be Performed?

You should perform edge operation and trough care weekly to guarantee peak performance. Regular maintenance helps prevent buildup, clogs, and equipment issues. Check the edges and troughs for debris and wear, and clean or adjust them as needed. Consistent care keeps your system running smoothly, extends its lifespan, and maintains efficiency. Make it a routine to inspect and service these components every week for the best results.

What Are Signs of Equipment Failure Needing Urgent Attention?

You notice strange noises, unusual vibrations, or persistent leaks—these are signs your equipment’s failing. Maybe your system’s pressure drops unexpectedly, or you see warning lights flashing. Don’t ignore these clues; they signal urgent issues that can lead to costly repairs or downtime. Act quickly—shut down the equipment safely, and call in a technician. Staying alert to these signs keeps your operation running smoothly and avoids disaster.

Can I Perform Maintenance Without Shutting Down the System?

You shouldn’t perform maintenance without shutting down the system, as it can be dangerous and may cause further damage. Always turn off and disconnect power before working on equipment to guarantee your safety. If you need to perform quick inspections or adjustments, follow proper lockout/tagout procedures. Regular maintenance is best done during scheduled shutdowns to prevent unexpected failures and ensure safe, effective repairs.

Which Safety Precautions Are Essential During Maintenance?

Think of maintenance as steering a busy river—safety precautions are your life jacket. Always lock out and tag electrical sources, wear protective gear, and verify system shutdowns before starting. Use insulated tools, keep a clear workspace, and stay alert for unexpected hazards. These steps guarantee you stay afloat, preventing accidents and ensuring smooth, safe maintenance, much like a skillful sailor safely guiding their vessel through calm waters.

How Do Environmental Factors Affect Equipment Longevity?

Environmental factors considerably impact your equipment’s longevity. Harsh weather like extreme heat, cold, or humidity accelerates wear and tear, causing corrosion or material fatigue. Dust, dirt, and debris can clog components, leading to overheating or mechanical failure. UV exposure weakens plastics and rubber parts. To extend your equipment’s lifespan, regularly inspect, clean, and protect it from adverse conditions, and consider using protective covers or shelters when possible.

Conclusion

By keeping up with this weekly checklist, you guarantee your edge operation and trough stay in top shape. Regular inspections, cleaning, and maintenance prevent costly repairs and keep your system running smoothly. Are you ready to take control and extend the lifespan of your equipment? Staying proactive not only saves you time and money but also guarantees peak performance. Don’t wait for problems to arise—your diligent care today secures a successful tomorrow.