To keep your booster pump running smoothly, regularly inspect components like pressure tanks, valves, and seals for wear or leaks. Clean out debris, intake screens, and make sure electrical connections are secure and free of corrosion. Lubricate moving parts, monitor pressure gauges, and replace worn seals promptly. Schedule professional checkups for peak performance. Doing these simple steps will help prevent breakdowns and extend your pump’s lifespan—exploring further will give you even more maintenance tips.

Key Takeaways

- Regularly inspect for leaks, corrosion, and damage at seals, joints, and pressure gauges.

- Ensure electrical connections are secure, check for proper circuit breaker operation, and verify control calibration.

- Clean intake screens and remove debris to prevent blockages and maintain optimal flow.

- Monitor pump performance, including flow rate and pressure, and replace worn seals or O-rings promptly.

- Lubricate moving parts as per manufacturer guidelines to reduce wear and ensure smooth operation.

Understanding Your Booster Pump’s Components

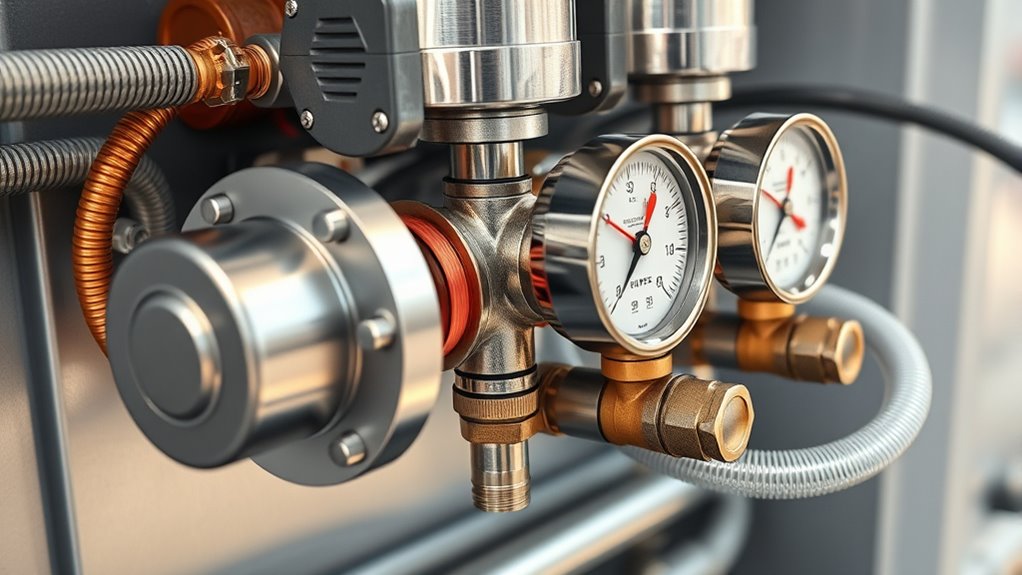

Understanding your booster pump’s components is essential for proper maintenance and troubleshooting. Knowing how each part functions helps you identify issues early. The pump’s calibration is critical to guarantee it delivers the correct pressure and flow rate. If performance drops, you might need to adjust or recalibrate the system. Additionally, familiarize yourself with key components like the pressure tank, valves, and motor. Over time, some parts may wear out or become damaged, requiring component replacement. Regularly inspecting these parts helps maintain ideal operation. Proper calibration is especially important for ensuring your system operates efficiently and effectively. By understanding how your booster pump’s components work together, you can address problems efficiently and prevent costly repairs. Proper maintenance, including precise pump calibration and timely component replacement, keeps your system running smoothly.

Regular Inspection and Visual Checks

You should regularly inspect your booster pump for leaks and make certain all connections are tight. Check the pressure gauges to confirm they’re within the recommended range, and look at the power connections for any signs of wear or damage. Staying vigilant with these visual checks helps keep your pump running smoothly and prevents costly breakdowns. Additionally, monitoring the performance of glycolic acid in your skincare routine can support your skin’s health, much like maintaining your pump ensures its optimal operation. Regular maintenance also involves checking for corrosion, which could compromise the pump’s integrity and lead to failures over time. Being attentive to proper cleaning techniques can further prolong the life of your equipment and ensure consistent performance. Incorporating energy-efficient components can also help reduce power consumption, making your maintenance routine more sustainable and cost-effective.

Check for Leaks

Are there visible signs of leaks on your booster pump? You need to perform regular visual checks to ensure leak detection and seal integrity. First, inspect all connection points, hoses, and fittings for any wet spots or drips. Second, look for corrosion or mineral buildup around seals and joints, which can indicate slow leaks. Third, listen for hissing sounds or unusual noises that suggest escaping air or fluid. Fourth, examine the pump housing for discoloration or wetness, signs of fluid escape. Regular inspection of seal integrity helps catch leaks early, preventing damage and guaranteeing peak performance. Additionally, monitoring pressure levels can help identify issues before they become serious. Using a visual inspection routine consistently allows for early detection of potential problems. Being aware of common leak sources can further aid in preventive maintenance and swift repairs. Implementing preventive maintenance practices ensures the longevity and efficiency of your booster pump. Maintaining these visual checks helps catch leaks early, preventing damage and guaranteeing peak performance. Addressing leaks promptly keeps your booster pump running smoothly and preserves its seal integrity. Regular inspection is key to reliable operation.

Inspect Pressure Gauges

Regularly inspecting your booster pump’s pressure gauges helps guarantee it’s operating within safe and efficient parameters. Check the gauges for any signs of damage, corrosion, or irregular readings. Accurate pressure gauge calibration is essential; if you notice inconsistent readings, recalibrate the gauges promptly. Conduct pressure fluctuation analysis during your inspections to identify any abnormal variations that could indicate underlying issues. Consistent monitoring ensures the pump maintains ideal performance and prevents potential failures. Visual checks should be part of your routine maintenance, and if you detect persistent pressure fluctuations, address them immediately. Proper gauge inspection helps you catch problems early, saving you time and costly repairs down the line. Staying vigilant with pressure gauge checks ensures your booster pump runs smoothly and reliably. Regular maintenance practices are vital for long-term system health and performance, including keeping an eye on system durability that can influence the overall system durability. Being aware of cheating behaviors can also be crucial for maintaining integrity and trust within team environments. Additionally, understanding air quality factors can help optimize pump operation and prevent unnecessary wear.

Examine Power Connections

To guarantee your booster pump operates safely and reliably, inspecting the power connections should be part of your routine maintenance. Regular visual checks help prevent issues like power surges or electrical failures. First, ensure the power cord and plug are undamaged and securely connected. Second, verify that the circuit breaker is in the ON position and hasn’t tripped. Third, look for signs of corrosion or burn marks around terminals, which indicate electrical problems. Fourth, test the circuit breaker periodically to confirm it trips properly during overloads. Address any loose connections or damage immediately, and consider installing surge protectors to safeguard against power surges. Incorporating electrical safety measures into your inspections can further reduce the risk of malfunctions. Regularly reviewing electrical system maintenance can help identify potential issues before they cause failures. Additionally, inspecting the power supply connections for proper grounding can prevent electrical hazards. Checking the connection integrity regularly ensures all components are functioning correctly and minimizes the chance of unexpected failures. Being aware of vendor reliability and service quality can help you select trustworthy components and support. Consistent inspection minimizes unexpected failures and keeps your booster pump running smoothly.

Cleaning and Removing Debris

You should regularly check your booster pump for blockages that could hinder performance. Make sure to clean the intake screen to prevent debris from entering the system. Keeping these parts clear helps your pump run smoothly and extends its lifespan.

Inspect for Blockages

Have you checked your booster pump for blockages lately? Blockage causes can hinder performance, so regular inspection is essential. Use appropriate inspection tools like a flashlight or mirror to spot debris or buildup. Here are steps to follow:

- Turn off the pump and disconnect power before inspection.

- Examine inlet and outlet ports for obstructions or debris.

- Check for signs of corrosion or buildup around seals and fittings.

- Clear any debris carefully, ensuring no damage to internal components.

Clean Intake Screen

When it’s time to guarantee peak performance, cleaning the intake screen is a crucial step. The intake screen filters debris and prevents particles from entering your pump, so keeping it clean is essential. To remove debris, turn off the pump and locate the intake screen, usually positioned at the inlet. Carefully remove the screen and inspect it for dirt, leaves, or other obstructions. Rinse it thoroughly with water to clear debris and ensure proper flow. Use a soft brush if needed to dislodge stubborn buildup. Once cleaned, reattach the intake screen securely. Regular debris removal prevents clogs and maintains ideal pump performance. By keeping your intake screen clean, you help your booster pump operate efficiently and extend its lifespan.

Lubricating Moving Parts

Regular lubrication of the moving parts in your booster pump is essential to guarantee smooth operation and prevent unnecessary wear. Establishing a consistent lubrication schedule ensures components stay well-oiled and functional. Use the correct oil type, usually specified by the manufacturer, to avoid damage and maximize efficiency. Follow these steps to maintain ideal lubrication:

- Check the lubrication schedule recommended in your manual.

- Clean all moving parts before applying new oil.

- Apply the specified oil type evenly to bearings, shafts, and gears.

- Avoid over-lubricating, which can attract dirt and cause malfunctions.

Checking and Replacing Seals and O-Rings

Checking and replacing seals and O-rings is essential for preventing leaks and maintaining your booster pump’s efficiency. Regular seal replacement ensures that your pump operates smoothly without fluid escaping, which can cause pressure drops or damage. During O-ring inspection, look for signs of wear, cracking, or deformation. If you notice any damage, it’s time to replace the O-ring to prevent leaks and maintain a tight seal. Use proper tools to remove old seals carefully, avoiding damage to surrounding parts. When installing new seals and O-rings, lubricate them with compatible lubricant to ensure proper seating. Consistent inspection and timely replacement keep your pump functioning reliably and extend its lifespan, saving you costly repairs and downtime.

Monitoring Pump Performance and Pressure

Are you actively monitoring your booster pump’s performance and pressure? Keeping an eye on flow rate and pressure fluctuations helps guarantee peak operation. Regular checks can catch issues early before they escalate. Here are key aspects to track:

- Observe steady flow rates to confirm consistent delivery.

- Watch for pressure fluctuations, which may indicate blockages or leaks.

- Use gauges to monitor pressure levels during operation.

- Record data periodically to identify trends or irregularities.

Testing Electrical Connections and Controls

To guarantee your booster pump operates safely and efficiently, you need to test its electrical connections and controls thoroughly. Start by inspecting wiring for loose or damaged connections, ensuring electrical safety. Check control calibration to verify the pump responds correctly to system demands. Use a multimeter to test voltage and continuity, confirming proper power flow. Properly calibrated controls prevent overworking the pump and help maintain ideal performance.

| Checkpoint | Action |

|---|---|

| Electrical safety | Inspect wiring for damage and secure connections |

| Control calibration | Verify response accuracy of control settings |

| Voltage & continuity | Use multimeter to test electrical parameters |

Scheduling Professional Servicing

Scheduling professional servicing for your booster pump is essential to guarantee it continues to operate efficiently and reliably. Regular maintenance helps extend the pump’s lifespan and manages costs by preventing costly repairs. When you schedule expert servicing, they will:

- Inspect critical components to identify wear and tear early

- Lubricate moving parts to reduce friction and prevent overheating

- Test and calibrate controls for peak performance

- Replace worn seals or filters to avoid leaks and contamination

These steps ensure your pump runs smoothly, avoiding unexpected breakdowns that could lead to expensive repairs. Routine professional servicing not only safeguards your investment but also supports effective cost management over the pump’s lifespan, keeping your system dependable and efficient.

Keeping Accurate Maintenance Records

Maintaining accurate records of your booster pump’s maintenance activities is essential for guaranteeing its ongoing performance and reliability. By keeping detailed logs, you can track when maintenance tasks, such as inspections, part replacements, or repairs, are completed. This helps you adhere to your maintenance schedule and avoid overlooked issues. Always record the pump manufacturer’s recommended service intervals and any specific instructions they provide. These records enable you to identify patterns or recurring problems that may require attention before they become serious. Additionally, having exhaustive documentation makes it easier for technicians to diagnose issues quickly during professional servicing. Staying organized with your maintenance logs ensures your booster pump remains in prime condition, extending its lifespan and maintaining consistent performance.

Frequently Asked Questions

How Often Should I Replace the Booster Pump’S Filters?

You should replace your booster pump’s filters regularly to guarantee peak performance. Typically, filter replacement depends on usage, but a good rule of thumb is every 3 to 6 months. Regular filter changes help prevent clogs, improve water quality, and extend your pump’s lifespan. Keep an eye on the filter’s condition, and replace it promptly when it shows signs of wear to maintain efficient operation and prolong your pump’s lifespan.

What Are the Signs of a Failing Booster Pump?

If your booster pump starts making unusual pump noise or you notice leak detection around the unit, these are signs it might be failing. You could experience decreased water pressure or inconsistent flow, indicating internal issues. Don’t ignore these signals; addressing them early helps prevent costly repairs. Regular inspections can catch problems before they become serious, ensuring your booster pump continues to operate efficiently and reliably.

Can I Upgrade My Booster Pump for Better Efficiency?

Did you know upgrading your booster pump can boost efficiency by up to 30%? If you’re concerned about pump noise and power consumption, upgrading is a smart move. A new, more efficient pump reduces noise and cuts energy costs, saving you money long-term. You’ll enjoy quieter operation and lower utility bills. So, if your current pump is noisy or consumes too much power, upgrading could be a worthwhile investment.

How Do Temperature Changes Affect Booster Pump Performance?

Temperature fluctuations can markedly impact your booster pump’s performance. When temperatures drop, the pump may become less efficient because thickening fluids increase resistance, making it harder to operate smoothly. Conversely, high temperatures can cause components to overheat, reducing pump efficiency and risking damage. To keep your booster pump running at its best, monitor temperature changes regularly and make sure it’s properly insulated or cooled as needed to maintain consistent pump efficiency.

What Safety Precautions Should I Follow During Maintenance?

When performing maintenance, you should follow safety precautions to protect yourself. Always wear protective gear like gloves and goggles to prevent injuries. Implement lockout procedures to guarantee the pump stays off and there’s no accidental startup. Make sure to disconnect power sources before beginning any work. These steps help you stay safe, avoid accidents, and ensure the maintenance is completed properly. Safety always comes first during any equipment upkeep.

Conclusion

Think of your booster pump as the heartbeat of your water system. Keep it healthy with regular checks, cleaning, and timely repairs, just like tending a garden. When you give it proper care, it’ll beat strong and steady, ensuring your water flows smoothly. Don’t wait for a breakdown—stay proactive with maintenance. Treat your pump well, and it’ll reward you with reliable performance, keeping your water supply flowing like a well-oiled machine.