To make cleaning easier, place your vacuum ports in accessible spots where you can reach them easily without moving furniture or fixtures. Use clear, bright labels and color coding to identify lines quickly. Keep lines straight, short, and avoid sharp bends or kinks to maintain airflow and prevent damage. Secure lines properly and steer clear of heat sources to prolong their lifespan. For more helpful tips, you’ll find useful strategies to optimize your system’s maintenance and longevity.

Key Takeaways

- Position ports in open, accessible wall or ceiling areas near main workspaces to facilitate quick connection and maintenance.

- Place ports at a height that balances ease of access with protection from accidental damage.

- Route lines straight with gentle curves, avoiding sharp bends to simplify cleaning and airflow maintenance.

- Use clearly visible, bold labels and color coding to quickly identify lines during cleaning or troubleshooting.

- Secure lines with clips or brackets to prevent movement, kinks, and wear, making cleaning and repairs easier.

Choose Accessible Locations for Vacuum Ports

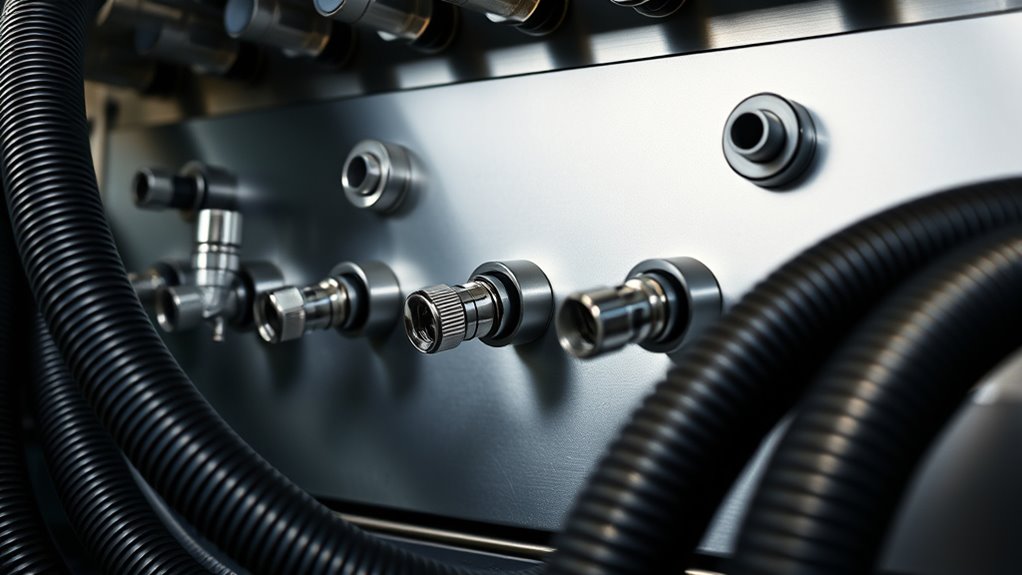

Choosing accessible locations for vacuum ports is crucial to guarantee easy installation and maintenance. You want to position ports where you can reach them without hassle, avoiding tight or awkward spots. Think about areas that are straightforward to access regularly, like open walls or ceilings near main workspaces. Placing ports high enough prevents accidental damage but still allows comfortable connection. Avoid installing ports behind furniture, inside tight corners, or in hidden areas, as these make routine checks and repairs difficult. Clear, open locations save you time and effort when setting up or troubleshooting. By planning carefully, you ensure your vacuum system remains functional and easy to maintain over time, reducing frustration and potential system downtime.

Use Clear and Visible Labeling

Using bright labels makes it easier to identify vacuum lines quickly. Color coding adds an extra layer of clarity, so you can distinguish ports at a glance. Clear and visible labeling helps prevent mistakes and improves overall safety. Additionally, incorporating regional flavors and traditions into your labeling system can enhance recognition and create a more intuitive setup.

Bright Labels Enhance Visibility

Bright labels on vacuum lines and ports make it easier to identify their functions quickly. When labels are clear and highly visible, you can avoid mistakes during maintenance or adjustments. Use labels with bold, contrasting colors or reflective materials that stand out against the background. This way, even in low light or messy environments, you can easily read the labels at a glance. Bright labels reduce confusion and save time, especially when working in busy or tight spaces. Ensure labels are large enough to read comfortably and are securely attached to prevent peeling or fading over time. Consistent use of bright, visible labels helps maintain an organized system, making cleaning and troubleshooting faster and more efficient. Proper label management ensures long-term clarity and reduces errors during operation.

Color Coding for Clarity

Have you ever struggled to quickly identify a vacuum line or port in a complex system? Color coding simplifies this by making identification instant. Use distinct colors for different functions, like red for exhaust, blue for intake, and green for auxiliary lines. Consistent color schemes prevent errors and save time during maintenance. To keep things clear, pair colors with labels and symbols. Here’s a simple example:

| Function | Color | Label Example |

|---|---|---|

| Exhaust | Red | “Exhaust Line” |

| Intake | Blue | “Intake Port” |

| Auxiliary | Green | “Auxiliary Line” |

| Ventilation | Yellow | “Vent Port” |

Stick to this system, and you’ll find troubleshooting and cleaning become much more straightforward. Implementing color coding techniques can also improve overall system safety and efficiency.

Opt for Straight and Short Runs

Choosing straight and short runs for your vacuum lines helps reduce potential leaks and pressure loss. Avoid unnecessary bends and curves to keep airflow steady and maintenance simple. Shorter lines also make troubleshooting easier and improve overall system reliability.

Minimize Bends and Curves

To guarantee ideal airflow and reduce potential vacuum leaks, it’s best to keep vacuum lines as straight and short as possible. Bends and curves create restrictions that slow airflow and increase the risk of leaks or blockages. When routing your lines, avoid sharp turns; instead, aim for smooth, gentle curves if bends are unavoidable. Keep lines close to the surface, minimizing unnecessary loops or twists that can trap dirt or moisture. Straight runs help maintain consistent vacuum pressure, ensuring your system operates efficiently. Additionally, shorter lines reduce the chance of leaks and make troubleshooting easier. Remember, the fewer bends and curves you have, the more reliable and easier to clean your vacuum system will be. Prioritizing straight, direct routes will improve performance and longevity. Incorporating vertical storage solutions can also help keep lines organized and accessible, further enhancing system reliability.

Choose Shorter Lengths

Opting for shorter vacuum lines directly enhances system efficiency and reliability. When lines are kept brief, there’s less resistance, which maintains strong suction power and reduces the risk of leaks. Short, straight runs also simplify troubleshooting and repairs, saving you time and effort. To optimize your setup, consider these tips:

- Use the shortest possible route between ports and equipment

- Avoid unnecessary extensions or loops

- Position vacuum ports close to the area they serve

- Plan your layout to minimize bends and curves

- Regularly check for and eliminate any excess length

- Additionally, choosing appropriate materials for your vacuum lines can further improve airflow and durability.

Simplify Maintenance Access

Have you considered how straight and short vacuum line runs can make maintenance much easier? When lines are direct and uncomplicated, you’ll find it simpler to access fittings and connections during routine checks or repairs. Shorter runs reduce the chance of leaks and blockages, which means fewer troubleshooting sessions. Straight lines eliminate kinks and twists that can trap debris or cause restrictions, ensuring ideal airflow. Position ports and lines close to the equipment they serve, so you don’t have to crawl into tight spaces to reach them. This setup saves time and effort during cleaning, adjustments, or troubleshooting. By planning your vacuum system with straight, short runs, you create a maintenance-friendly layout that keeps your setup efficient and easy to service. Proper filtration also plays a crucial role in protecting your equipment from contaminants and ensuring smooth operation.

Avoid Sharp Bends and Kinks in Lines

Avoiding sharp bends and kinks in vacuum lines is essential for maintaining proper airflow and system efficiency. When lines are bent sharply or kinked, airflow slows down or stops, reducing performance and risking damage. To keep lines clear and functional:

- Use gentle curves instead of tight angles

- Secure lines with clips to prevent shifting

- Avoid pinching lines under heavy objects

- Choose flexible tubing that resists kinking

- Regularly inspect lines for any signs of deformation

- Proper placement and handling can also prevent airflow obstruction, ensuring optimal system operation.

Secure Lines to Prevent Movement and Wear

Securing vacuum lines properly helps prevent movement that can cause wear and potential damage over time. Use clips, brackets, or zip ties to firmly hold lines in place, especially at connection points and along surfaces with vibrations or movement. Avoid letting lines dangle freely, as movement can lead to kinks or stress on the fittings. Check that lines are routed away from sharp edges or hot surfaces that could cause deterioration. Regularly inspect secured lines for signs of loosening or wear, and tighten or replace as needed. Properly anchored lines reduce the risk of accidental disconnections and extend their lifespan. Keeping lines secure ensures they stay intact, functioning efficiently, and minimizing maintenance needs over time. Incorporating proper routing techniques can further improve the longevity of vacuum lines by reducing strain and preventing unnecessary wear.

Maintain Adequate Clearance From Heat Sources

Keeping vacuum lines and ports clear of heat sources is essential to prevent damage and guarantee proper function. Excessive heat can cause materials to soften, warp, or crack, leading to leaks or failure. To protect your system, avoid placing vacuum lines near radiators, exhaust vents, or direct sunlight. Ensure lines run away from motors or heating elements that generate high temperatures. Proper spacing helps maintain the integrity of the hoses and ports, reducing risk of costly repairs. Additionally, understanding Mazda Tuning practices can help optimize placement for better performance and durability.

Regularly Inspect and Replace Aging Hoses

Regularly inspecting your vacuum hoses helps prevent unexpected failures that can lead to system malfunctions or costly repairs. Look for cracks, tears, or soft spots that indicate wear and deterioration. Bent or swollen hoses may also signal aging or blockages. If you notice any damage, replace the hose promptly to maintain ideal airflow and system efficiency. Keep in mind that hoses can become brittle over time, making them more prone to cracking during routine handling. Check connections to ensure they fit snugly without leaks. Replacing aging hoses not only improves performance but also reduces the risk of contamination or debris entering sensitive components. Regular inspections save you time and money by catching issues early before they escalate into major repairs. Additionally, maintaining proper HEPA filtration ensures your system continues to operate effectively and captures fine particles for cleaner air.

Incorporate Quick-Disconnect Fittings for Ease

Incorporating quick-disconnect fittings into your vacuum system can greatly simplify maintenance and repairs. They allow you to easily disconnect hoses and components without tools, saving time and reducing frustration. These fittings help prevent damage caused by forcing connections or twisting hoses. You can quickly swap out sections during cleaning or repairs, keeping your system running smoothly.

Consider these benefits:

- Easy to disconnect for cleaning or replacement

- Reduces wear on hoses and ports

- Speeds up maintenance tasks

- Minimizes risk of leaks

- Allows for modular system upgrades

Plan for Future Maintenance and Upgrades

Planning for future maintenance and upgrades guarantees your vacuum system remains efficient and adaptable. When installing lines and ports, consider accessibility for inspections and repairs. Leave extra space around connections to make tightening or replacing fittings easier. Use durable materials that can handle upgrades without needing complete replacement. Labeling lines clearly helps you identify and troubleshoot issues quickly later on. Think about potential system expansions—leave room for additional ports or higher-capacity lines. Incorporate modular fittings that allow quick swaps or upgrades. Regularly review your setup to identify areas prone to clogging or wear. By designing with future needs in mind, you minimize downtime and reduce costly modifications down the road. Proper planning today ensures your vacuum system stays reliable and easy to maintain for years to come.

Frequently Asked Questions

How Do I Prevent Vacuum Line Leaks Over Time?

To prevent vacuum line leaks over time, regularly inspect your hoses and connections for cracks or wear. Make sure all fittings are tight and secure, replacing any damaged or aging hoses promptly. Use high-quality clamps to guarantee a snug fit, and avoid kinking or twisting lines. Maintaining a clean environment around your vacuum system also helps prevent debris from causing leaks or damage, keeping everything functioning smoothly.

What Materials Are Best for Durable Vacuum Lines?

You should choose materials like reinforced rubber, silicone, or braided polyurethane for durable vacuum lines. These materials resist cracking, kinking, and wear over time, ensuring longevity. Silicone hoses are flexible and withstand high temperatures, while reinforced rubber offers excellent durability and chemical resistance. Braided polyurethane combines flexibility with strength, making it ideal for demanding applications. Selecting high-quality materials helps prevent leaks and keeps your vacuum system operating smoothly longer.

Can Vacuum Lines Be Customized for Specific Equipment?

Absolutely, you can customize vacuum lines for specific equipment—if you’re into turning your workspace into a DIY maze. You’ll need to select the right diameter, flexible material, and connectors. Just guarantee you measure precisely and choose compatible fittings. While it’s a bit of a puzzle, customizing ensures a perfect fit and easier maintenance. So, go ahead, get creative—your equipment will thank you with smoother operation and fewer headaches!

How Do Temperature Variations Affect Vacuum Line Performance?

Temperature variations can substantially impact your vacuum line performance. When it’s cold, lines may become brittle or crack, reducing efficiency. In hot conditions, lines can soften or expand, causing leaks or disconnections. You need to monitor these changes closely, and consider using materials suited for your temperature range. Regular inspections and proper insulation help maintain ideal performance, ensuring your vacuum system remains reliable regardless of temperature fluctuations.

Are There Safety Concerns With High-Pressure Vacuum Systems?

A stitch in time saves nine, and safety’s no different. High-pressure vacuum systems can pose risks if not handled properly. You should always wear protective gear, confirm pressure gauges are functioning, and follow manufacturer guidelines. Regular maintenance prevents accidents, and never bypass safety valves. Remember, safety isn’t just a precaution—it’s a priority. By staying vigilant, you keep your workspace safe and your equipment in top shape.

Conclusion

Think of your vacuum lines as the veins of your system, carrying life and efficiency. By placing and maintaining them thoughtfully, you guarantee smooth flow and easy cleaning, like a well-tuned heartbeat. When you prioritize accessibility, clarity, and durability, you’re nurturing a resilient network that endures over time. Remember, every well-placed port and secure connection is a symbol of your commitment to clarity and function—keeping your system healthy, vibrant, and ready to serve.