To get a perfect, even sheet over the edge with hydraulics, you need to understand the system’s key components, select the right fluid, and set up everything correctly. Control pressure and flow carefully, use flow control valves, and monitor gauges regularly. Keep the system clean and leak-free, and avoid common mistakes like air pockets or pressure fluctuations. Mastering these basics guarantees smooth operation—continue exploring to learn how to fine-tune your setup for an flawless finish.

Key Takeaways

- Use flow control valves and pressure gauges to regulate and maintain consistent fluid flow for a smooth, even sheet.

- Regularly inspect hoses, fittings, and seals to prevent leaks and air pockets that cause uneven surfaces.

- Maintain proper hydraulic fluid viscosity and compatibility to ensure stable, uniform pressure during operation.

- Calibrate and monitor pump performance and pressure settings, adjusting gradually for uniform flow and minimal turbulence.

- Follow safety and maintenance protocols, including cleaning filters and checking system components, to ensure consistent, high-quality sheets.

Understanding Hydraulic Systems and Their Components

Have you ever wondered how hydraulic systems convert fluid power into mechanical motion? It’s all about their key components working together efficiently. You start with the reservoir, which holds the hydraulic fluid. The pump then draws fluid from the reservoir and pressurizes it, creating the force needed for movement. Valves control where the fluid flows, directing it to cylinders or motors. These actuators transform hydraulic energy into mechanical work, moving loads or powering machinery. Hoses and pipes connect everything, ensuring fluid flows smoothly. You also find filters that keep the fluid clean, preventing damage to components. Understanding these parts helps you grasp how hydraulics deliver precise, powerful force in many industrial applications. Each component plays an essential role in making hydraulic systems reliable and effective. Additionally, proper maintenance of hydraulic components is crucial for optimal system performance and longevity.

Choosing the Right Hydraulic Fluid for Your Project

Choosing the right hydraulic fluid depends on understanding its viscosity, which affects flow and system performance. You also need to guarantee the fluid is compatible with your equipment to prevent damage and leaks. Additionally, consider environmental impacts to select a fluid that minimizes environmental risks and meets safety standards. Using appropriate eye patches can enhance your routine by providing hydration and reducing signs of fatigue around the eyes.

Fluid Viscosity Essentials

Selecting the right hydraulic fluid depends heavily on understanding viscosity—the fluid’s resistance to flow. Choosing a fluid that’s too thick can cause sluggish operation, while one that’s too thin may lead to leaks or insufficient lubrication. To get it right, consider these points:

- Check the manufacturer’s recommended viscosity range for your equipment.

- Understand that viscosity varies with temperature—select a fluid with stable viscosity across operating conditions.

- Use multigrade fluids if your system operates in a wide temperature range.

- Remember, proper viscosity ensures smooth motion, reduces wear, and prevents system failure.

- Additionally, selecting a fluid with appropriate filtration capabilities can help maintain optimal air quality and extend component lifespan.

Getting viscosity right is crucial for peak performance and longevity. Always verify your fluid’s specifications and adjust based on operational environment for the best results.

Compatibility With Equipment

Ever wonder how to guarantee your hydraulic system runs smoothly and reliably? The key is choosing the right hydraulic fluid compatible with your equipment. Not all fluids work with every machine, so check your equipment’s specifications or manufacturer’s recommendations. Using incompatible fluid can cause seals to degrade, pumps to wear out prematurely, or valves to stick. Pay attention to the fluid’s type, such as mineral-based, synthetic, or water-based, and ensure it matches the system’s requirements. Compatibility also involves checking for additives, detergents, and corrosion inhibitors that won’t harm your equipment. When in doubt, consult your equipment manual or a hydraulic specialist. Properly matched fluid improves efficiency, extends the lifespan of components, and helps you avoid costly breakdowns. Additionally, understanding the benefits of proper fluid selection can lead to more efficient operation and longer equipment life.

Environmental Impact Factors

Have you considered how your choice of hydraulic fluid impacts the environment? The right fluid can reduce pollution and promote sustainability. When selecting, keep these factors in mind:

- Biodegradability: Choose fluids that break down naturally to prevent long-term environmental damage.

- Toxicity: Opt for low-toxicity options to protect wildlife and water sources.

- Spill resistance: Use fluids with high viscosity index and low volatility to minimize spills and evaporation.

- Disposal ease: Select fluids that are easier to recycle or dispose of responsibly, reducing landfill waste.

- Environmental impact factors are essential considerations to ensure your hydraulic system aligns with sustainable practices.

Setting Up Your Hydraulic Equipment Correctly

To guarantee your hydraulic system operates efficiently and safely, proper setup is essential. Begin by inspecting all components for damage or leaks before installation. Ensure hoses and fittings are compatible and securely tightened to prevent leaks or pressure loss. Correctly position the hydraulic pump, making sure it’s level and stable to avoid vibration and uneven wear. Fill the system with the recommended hydraulic fluid, checking for proper levels and air bubbles. Bleed the system to remove trapped air, which can cause inconsistent performance. Double-check all connections, fittings, and couplings for tightness. Additionally, implementing preventive maintenance practices can help identify potential issues early and prolong equipment lifespan. Finally, refer to the manufacturer’s instructions to confirm you’ve followed all setup procedures precisely. Proper setup minimizes downtime, extends equipment life, and guarantees smooth, even sheet production.

Mastering Proper Pressure and Flow Control

To keep your hydraulic system running smoothly, you need to master proper pressure and flow control. This means adjusting pressure settings correctly, regulating hydraulic flow, and consistently monitoring system performance. When you fine-tune these points, you’ll prevent issues and guarantee peak operation. Incorporating sound vibrations principles can also enhance system efficiency by reducing vibrations and noise.

Adjusting Pressure Settings

Adjusting pressure settings is essential for ensuring your hydraulic system operates smoothly and safely. Proper pressure control prevents leaks, reduces wear, and maintains consistent sheet quality. To set your pressure correctly:

- Start with the manufacturer’s recommended pressure range.

- Gradually increase pressure while monitoring system response.

- Watch for signs of overpressure, like leaks or slow movement.

- Use a pressure gauge to verify the exact setting.

Regulating Hydraulic Flow

Proper regulation of hydraulic flow ensures your system responds accurately and maintains ideal performance. To achieve this, you need to control the flow rate with precision. Use flow control valves to adjust how much fluid moves through the system at any given time. These valves allow you to fine-tune speeds, preventing sudden movements or sluggish responses. Make certain the valves are correctly installed and maintained for smooth operation. Additionally, selecting the right size and type of valve for your application is vital. Always match the flow control settings to the system’s requirements to avoid pressure drops or flow restrictions. Regularly inspect and calibrate your flow controls so your system consistently performs at its best, delivering smooth, even sheets over the edge. Proper regulation also helps prevent issues related to system reliability and ensures consistent operation over time.

Monitoring System Performance

Monitoring system performance is essential to guarantee your hydraulic system operates at ideal pressure and flow levels. Regular checks help you catch issues early and maintain efficiency. To do this effectively:

- Use pressure gauges to verify system pressures match specifications.

- Monitor flow meters to ensure consistent fluid movement.

- Inspect for leaks or blockages that could disrupt flow.

- Record readings periodically to identify trends and deviations.

- Incorporate digital literacy tools to track system data and improve diagnostic accuracy.

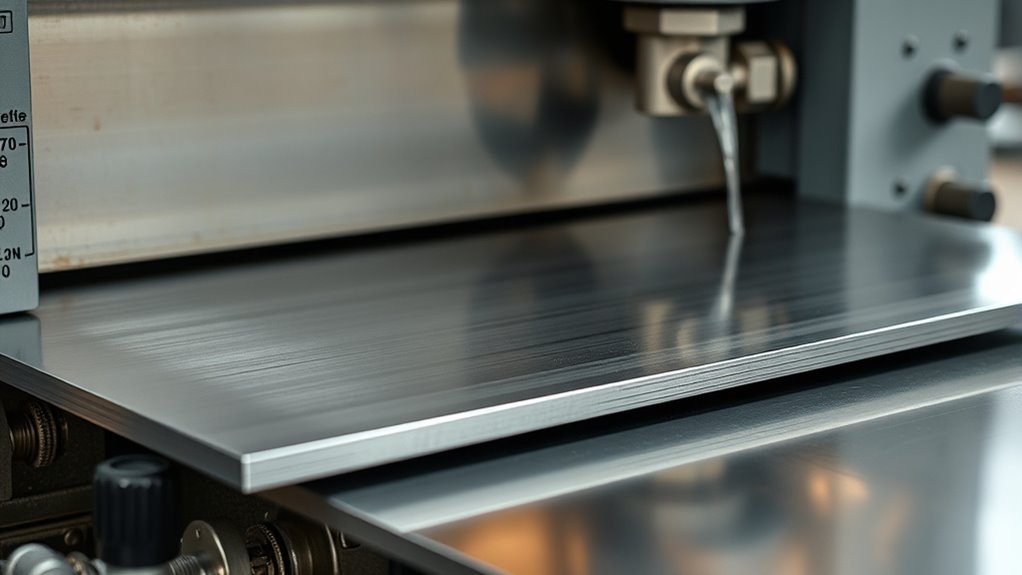

Techniques for Achieving a Smooth, Even Sheet

To achieve a smooth, even sheet in hydraulic processes, you need to focus on maintaining consistent flow and pressure throughout the system. Start by ensuring your hydraulic pump is properly calibrated and functioning efficiently. Use flow control valves to regulate the amount of fluid passing through different sections, preventing sudden surges or drops. Keep your system free of leaks and air pockets, as these can disrupt pressure stability. Regularly monitor pressure gauges to detect fluctuations early. Adjust your settings gradually rather than abruptly to promote uniform flow. Properly balancing your hydraulic components minimizes turbulence and guarantees the sheet forms evenly over the edge. Consistent operation and vigilant system checks are key to producing a flawless, level sheet every time. Additionally, understanding hydraulic system fundamentals can help troubleshoot issues and optimize performance.

Common Mistakes to Avoid When Using Hydraulics

One common mistake is neglecting to check for leaks and air pockets, which can cause pressure fluctuations and uneven results. If you overlook these issues, your hydraulic system won’t operate smoothly, leading to uneven sheets or process delays. To avoid this, focus on:

- Regularly inspecting hoses and fittings for leaks.

- Ensuring all air is purged from the system before operation.

- Using proper sealing techniques to prevent future leaks.

- Monitoring pressure gauges to catch fluctuations early.

Neglecting these steps can compromise your entire process, resulting in inconsistent sheet quality and potential equipment damage. Always verify the system’s integrity before starting, and maintain vigilance throughout operation to guarantee ideal, even results.

Regular Maintenance and Troubleshooting Tips

Regular maintenance is essential to keep your hydraulic system running smoothly and prevent costly breakdowns. Start by regularly inspecting hoses and fittings for leaks, cracks, or wear. Keep the fluid clean by checking levels daily and changing it according to the manufacturer’s schedule. Use the right type of hydraulic fluid, as specified, to guarantee best performance. Monitor pressure gauges to catch irregularities early. If you notice sluggish operation or unusual noises, troubleshoot by checking for air in the system or contaminated fluid. Always tighten fittings securely and replace worn components promptly. Maintaining a clean work environment helps prevent debris from contaminating the system. Consistent checks and proactive replacements will extend your equipment’s lifespan and keep your sheet over the edge perfectly even.

Tips for Fine-Tuning for a Perfect Finish

Ever wonder how to achieve that perfectly smooth hydraulic finish? Fine-tuning is key. First, check your hydraulic fluid levels—low fluid can cause uneven flow. Next, adjust your pressure settings incrementally to avoid overcompensation. Third, verify your nozzle alignment; a slight misalignment can create uneven sheets. Finally, monitor your flow rate; consistent flow ensures a smooth, even finish. By making small, deliberate adjustments in these areas, you can markedly improve the quality of your sheet. Remember, patience is essential—fine-tuning takes time, but the results are worth it. Focus on precision with each tweak, and you’ll consistently achieve that sleek, perfect edge every time.

Safety Measures and Best Practices

Ensuring safety when working with hydraulic systems is essential to prevent accidents and equipment damage. Always wear protective gear, including gloves and safety glasses, to shield yourself from high-pressure fluid leaks or unexpected releases. Before starting, inspect hoses, fittings, and cylinders for wear or damage, replacing any compromised parts. Use proper tools and avoid shortcuts that could cause leaks or failures. Never work on a hydraulic system under pressure, and always relieve pressure before maintenance. Keep your workspace clean and organized to prevent slips or trips. Follow manufacturer instructions and safety guidelines rigorously. Regular training helps you stay aware of potential hazards and best practices. By prioritizing safety, you protect yourself and ensure your hydraulic system operates reliably and efficiently.

Frequently Asked Questions

How Do Temperature Changes Affect Hydraulic Fluid Performance?

Temperature changes can substantially impact hydraulic fluid performance. When it’s cold, the fluid thickens, making it harder for your system to operate smoothly and potentially causing sluggish responses. In hot weather, the fluid thins out, risking leaks and reduced lubrication. To maintain ideal performance, you should regularly check fluid temperature, use the right type of hydraulic fluid for your climate, and consider temperature regulation systems to keep everything running efficiently.

What Are Signs of Hydraulic System Contamination?

You might notice sluggish operation, unusual noises, or inconsistent movement in your hydraulic system—these are signs of contamination. Dark or cloudy fluid, metal shavings, or debris in the reservoir point to dirt or particles infiltrating the system. Regularly inspecting and maintaining your hydraulic fluid helps prevent contamination. If you observe these symptoms, acting quickly by flushing and replacing the fluid guarantees your system stays efficient and avoids costly damages.

Can Hydraulic Systems Be Used for Delicate Sheet Finishes?

Yes, hydraulic systems can be used for delicate sheet finishes if you select the right components and settings. You should use precise control valves, low-pressure systems, and gentle actuators to prevent damage or marks. Regular maintenance and proper calibration guarantee smooth operation. By fine-tuning pressure and flow rates, you can achieve a high-quality, even finish without compromising the sheet’s delicate surface.

How Do I Select the Right Hydraulic Pump Size?

You select the right hydraulic pump size by first calculating your system’s flow rate and pressure requirements. Consider your load’s weight, speed, and cycle times to determine the needed capacity. Always choose a pump with slightly higher specifications than your calculations to guarantee efficiency and longevity. Consulting manufacturer guidelines or an engineer can help you fine-tune the choice, preventing underperformance or damage.

Are There Eco-Friendly Hydraulic Fluid Options Available?

Yes, eco-friendly hydraulic fluids are available. You can opt for biodegradable options made from plant-based oils or synthetic fluids designed to reduce environmental impact. These fluids work effectively while decreasing pollution risks. When choosing, consider compatibility with your system and temperature requirements. Using eco-friendly hydraulic fluids helps you operate sustainably without compromising performance, making your equipment more environmentally responsible and aligning with eco-conscious practices.

Conclusion

Mastering hydraulics blends precision with patience, where small adjustments lead to flawless results. While your setup ensures safety and efficiency, neglecting proper technique can cause uneven sheets and costly errors. Balancing careful maintenance with confident operation, you’ll achieve a perfect, even finish that elevates your work from functional to exceptional. In this dance of pressure and flow, your skill transforms simple machinery into a tool of artistry—proof that mastery turns the mundane into the magnificent.