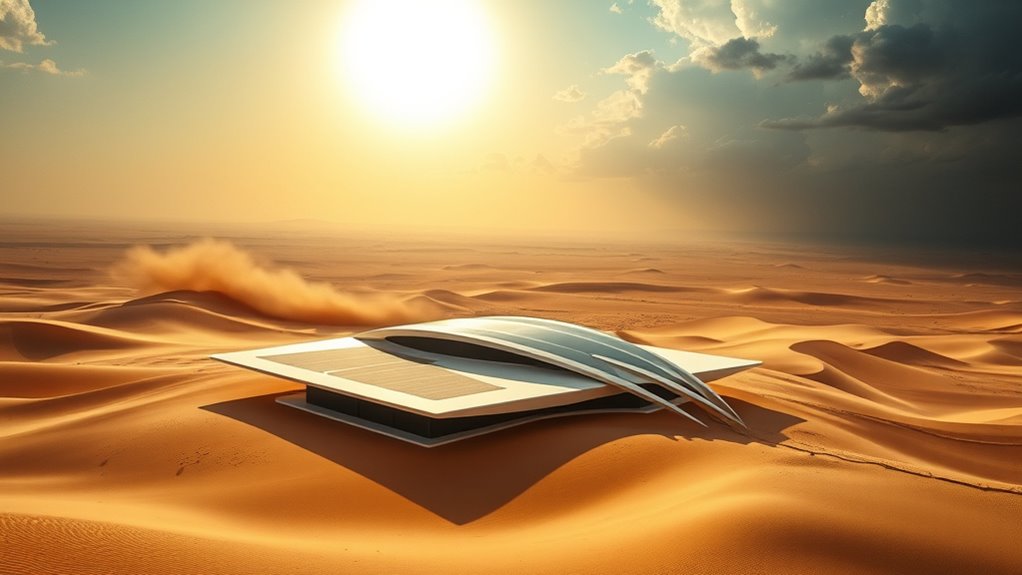

When planning desert installations, focus on designing dust-resistant structures with sealed enclosures, filtration systems, and strategic placement to reduce dust buildup. Use reflective roofs and shading for heat management, and incorporate natural ventilation and insulation. To prepare for monsoon impacts, guarantee proper drainage, elevate critical equipment, and seal vulnerabilities. Regular maintenance and monitoring help sustain operations. Stay tuned to discover detailed strategies for thriving in harsh desert environments.

Key Takeaways

- Design dust-resistant structures with sealed enclosures, filtration systems, and strategic placement to minimize dust accumulation.

- Use reflective roofing, shading, and high-quality insulation to manage heat and protect sensitive equipment.

- Ensure proper site grading, install drainage solutions, and elevate infrastructure to mitigate monsoon-related flooding.

- Incorporate durable, water-resistant materials and landscape features that absorb excess moisture during storms.

- Implement regular maintenance, remote monitoring, and emergency plans to sustain infrastructure resilience against desert conditions.

Assessing the Environmental Challenges of Desert Installations

While desert installations offer promising solutions for renewable energy and infrastructure development, they also pose significant environmental challenges. You need to consider how large-scale projects can disrupt local ecosystems and wildlife habitats. Construction can disturb the fragile desert soil, leading to increased erosion and dust storms that affect air quality. Water usage is another concern, as installing infrastructure often requires substantial water resources, which are scarce in desert regions. Additionally, the heat generated by solar panels and other equipment can alter local microclimates, impacting plant and animal life. It’s vital to take into account thorough environmental assessments before starting projects to understand potential impacts. Recognizing the importance of environmental impact assessments can help mitigate ecological damage. By understanding these challenges, you can develop strategies to minimize ecological damage and promote sustainable desert installations.

Designing Dust-Resistant Structures and Systems

Designing dust-resistant structures and systems is essential for maintaining efficiency and longevity in desert installations. You should prioritize sealed enclosures, smooth surfaces, and minimal openings to prevent dust ingress. Using materials like coated metals or treated concrete reduces particle adherence. Incorporate filtration systems, such as HEPA filters, to trap airborne dust before it enters sensitive equipment. Proper placement and orientation of structures can also reduce dust accumulation, shielding key components from prevailing winds. Consider the following strategies:

| Strategy | Benefit |

|---|---|

| Sealed enclosures | Prevent dust entry, protect sensitive systems |

| Elevated platforms | Minimize dust contact from ground level |

| Dust barriers and shields | Block dust pathways around critical areas |

| Regular cleaning and maintenance | Remove accumulated dust, ensure efficiency |

Additionally, implementing vertical storage solutions can help keep equipment and materials off the ground, reducing exposure to dust and making cleaning easier.

Implementing Effective Heat Management Solutions

Effective heat management is crucial for maintaining the performance and durability of desert installations. You should focus on designing systems that minimize heat absorption, such as reflective roofing and shading devices. Incorporate natural ventilation and airflow strategies to dissipate heat effectively. Use high-quality insulation materials to protect sensitive equipment from temperature extremes. Installing cooling systems like evaporative coolers or air conditioning can help, but they must be energy-efficient to avoid excessive power use. Regular maintenance ensures cooling systems operate at their best. Additionally, choose materials with high thermal resistance and ensure proper placement of equipment to reduce heat exposure. By implementing these solutions, you’ll safeguard your installation against the intense desert heat, ensuring longevity and reliable operation in harsh conditions. Understanding credit card terms can also help optimize energy management strategies by tracking operational costs efficiently.

Preparing for and Mitigating Monsoon Impacts

Preparing for and mitigating monsoon impacts is essential to protect your desert installation from heavy rains, flooding, and humidity. Start by evaluating your site’s drainage capacity and ensuring proper grading to direct water away from structures. Install reliable gutters and downspouts, and seal any vulnerabilities in roofs, walls, and foundations to prevent leaks. Consider elevating equipment and critical infrastructure to reduce flood risk. Use water-resistant materials where possible, and design landscaping to absorb excess moisture. Keep stormwater management systems clear and functional. Planning ahead also involves creating emergency response plans and stockpiling essentials. Additionally, understanding the role of necessary cookies can help you monitor site performance and security during extreme weather events. By proactively addressing these issues, you minimize damage, reduce downtime, and ensure your installation remains resilient during the monsoon season.

Maintenance and Monitoring for Long-Term Durability

Regular maintenance and vigilant monitoring are essential to ensuring your desert installation stands the test of time. Regular inspections help you identify issues like dust buildup, corrosion, or material fatigue early, preventing costly repairs. Clean filters, check seals, and clear debris frequently to keep systems functioning efficiently. Use remote sensors or monitoring tools to track temperature, humidity, and structural integrity continuously. Address any irregularities promptly to avoid long-term damage caused by heat stress or dust intrusion. Keep detailed maintenance logs to track repairs and monitor trends over time. Staying proactive reduces downtime and extends your installation’s lifespan. Incorporating professional assessment into your maintenance routine can further help identify potential vulnerabilities before they escalate. Remember, consistent upkeep tailored to desert conditions safeguards your investment against the harsh environment, ensuring reliable performance year after year.

Frequently Asked Questions

What Are the Cost Implications of Desert Installation Adaptations?

The cost implications of desert installation adaptations can be significant. You’ll likely face higher expenses for specialized materials, enhanced cooling systems, and protective enclosures to withstand dust and heat. Additionally, increased maintenance and occasional replacement parts add to costs over time. While upfront investments are higher, these adaptations help prevent damage, reduce downtime, and extend equipment lifespan, ultimately saving you money in the long run.

How Do Local Regulations Influence Desert Installation Planning?

You’ll find local regulations act like a guiding compass, shaping your desert installation plans. They set strict standards for dust control, heat resilience, and monsoon protection, making you adapt your approach. Steering through these rules can feel like balancing on shifting sands, but doing so ensures safety and compliance. Embrace the challenge, and you’ll create a sturdy, regulation-ready installation that withstands the desert’s relentless elements.

What Advanced Materials Enhance Durability in Desert Environments?

You should consider using advanced materials like high-performance coatings, reinforced composites, and heat-resistant alloys to enhance durability in desert environments. These materials resist extreme heat, abrasive dust, and moisture from monsoons, ensuring your installations last longer. By choosing innovative options such as ceramic coatings or fiber-reinforced plastics, you can prevent corrosion, reduce maintenance needs, and improve overall resilience, making your desert projects more reliable and sustainable over time.

How Can Community Engagement Improve Project Outcomes?

Did you know community engagement can boost project success by up to 30%? You can improve outcomes by involving locals early, listening to their needs, and encouraging participation. When you foster trust and collaboration, residents are more likely to support and maintain the project. This shared ownership leads to better resource management, fewer conflicts, and long-term sustainability, making your project more resilient amid desert challenges like dust, heat, and monsoons.

What Are Future Technological Innovations for Desert Installations?

Future technological innovations for desert installations include advanced cooling systems that conserve water and energy, solar-powered autonomous maintenance drones, and smart sensors that monitor environmental conditions in real-time. You’ll see improved insulation materials to withstand extreme temperatures and dust-resistant equipment that reduces downtime. These innovations will enhance efficiency, durability, and sustainability, helping you adapt to harsh desert environments while minimizing ecological impact and operational costs.

Conclusion

Think of your desert installation like a resilient cactus—built to withstand harsh conditions and thrive amidst adversity. By carefully evaluating environmental challenges, designing dust-resistant structures, managing heat, and preparing for monsoons, you ensure long-term durability. Just as a cactus stores water for tough times, your proactive planning keeps your project thriving despite dust storms, scorching days, or heavy rains. With the right strategies, you’ll turn the desert’s obstacles into opportunities for resilience and success.