To spot early trouble with edge wear and tear, you should regularly inspect for chips, cracks, or dull areas along the edges, which show signs of material fatigue. Keep an eye on performance changes like slower operation, increased noise, or vibrations that hint at internal issues. Use tools such as magnifiers or ultrasonic gauges for precise checks, and maintain logs of wear patterns. Staying proactive helps prevent bigger problems — and there’s more to uncover if you continue exploring these techniques.

Key Takeaways

- Inspect edges regularly for chips, cracks, dents, or discoloration indicating early damage.

- Look for irregularities like burrs or jagged edges that compromise safety and signal wear.

- Monitor contact points for uneven wear, shiny spots, or scratches suggesting friction or fatigue.

- Use magnifiers, ultrasonic gauges, or calipers for precise detection of surface and subsurface issues.

- Conduct routine maintenance such as lubrication and protective coatings to prevent early wear and tear.

Recognizing Visible Signs of Edge Damage

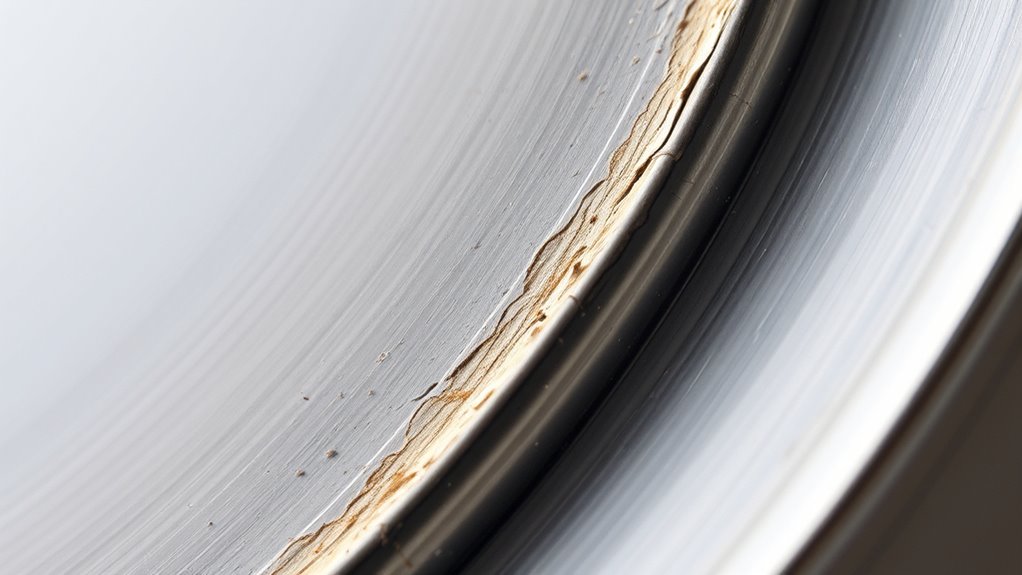

When inspecting your equipment, recognizing the visible signs of edge damage is vital, as these can indicate underlying issues that may worsen if left unaddressed. Look closely at the edges for chips, cracks, or dents—these imperfections often signal excessive wear or impact. Discoloration or dullness on the edge can also be warning signs of material fatigue. Pay attention to any irregularities like burrs or jagged edges, which can compromise safety and performance. Sometimes, damage appears as slight deformation or bent edges, hinting at more extensive internal issues. Catching these signs early helps prevent further deterioration and costly repairs. Regular visual checks ensure you catch problems before they escalate, keeping your equipment safe and functioning at its best. Additionally, understanding energy efficiency can help you identify equipment issues that lead to increased energy consumption and reduced system lifespan.

Monitoring Performance Changes Over Time

Observing how your equipment performs over time provides valuable insights beyond what visible signs alone can reveal. Pay attention to changes in efficiency, noise levels, or unusual vibrations. If you notice your machine slowing down or requiring more frequent adjustments, it may indicate developing issues. Track performance metrics regularly, such as cycle times or output quality, to identify patterns or declines. Keeping a detailed log helps you spot gradual changes that aren’t immediately obvious. Monitoring performance isn’t just about reacting to problems; it’s about catching early signs of wear before they escalate. Regularly reviewing performance data can help you identify trends and anticipate maintenance needs more accurately. By staying proactive and attentive, you can schedule maintenance at the right time, reducing downtime and extending your equipment’s lifespan. Consistent observation is key to maintaining *ideal* performance and avoiding costly repairs.

Assessing Contact Points and Wear Patterns

Evaluating contact points and wear patterns is essential for detecting early signs of equipment deterioration. By closely examining these areas, you can identify uneven wear, material loss, or misalignment that signal trouble ahead. Look for irregularities such as shiny spots, grooves, or scratches, which indicate excessive friction. Focus on contact zones that bear the most load, as these are prone to faster wear. To stay organized, consider this overview:

| Contact Point | Wear Pattern | Possible Issue |

|---|---|---|

| Edge interface | Shiny, polished | High friction, misalignment |

| Contact surface | Grooves | Material fatigue or debris |

| Bearing area | Scratches | Insufficient lubrication |

| Clamping zone | Uneven wear | Unequal pressure distribution |

| Fastener points | Looseness | Vibration or improper tightening |

Regular inspection helps catch problems early, preserving equipment longevity. Understanding these wear patterns allows for more targeted maintenance and prolongs the lifespan of your devices.

Using Tools and Techniques for Accurate Inspection

To guarantee accurate inspection of equipment wear, selecting the right tools and techniques is essential. Start with handheld magnifiers or optical microscopes for detailed surface analysis, helping you spot early signs of damage. Use ultrasonic thickness gauges to measure material integrity beneath the surface, catching issues before they become visible. Digital calipers and micrometers provide precise measurements of wear depth and contact points, ensuring consistency. Non-destructive testing methods, like dye penetrant or magnetic particle inspection, reveal cracks or flaws hidden to the naked eye. Combining visual inspections with these tools allows you to gather exhaustive data quickly and accurately. Always calibrate your instruments regularly to maintain reliability. This approach ensures you identify early trouble accurately, preventing costly repairs and extending equipment lifespan.

Preventative Measures to Minimize Wear and Tear

Implementing preventative measures is essential to minimize wear and tear on equipment. Regular lubrication reduces friction, preventing premature damage to edges. Keep your tools clean and free of debris, which can cause abrasion and accelerate deterioration. Schedule routine inspections to catch early signs of wear, allowing you to address issues before they worsen. Adjust operating speeds and loads to stay within recommended limits, reducing undue stress on components. Using protective coatings or covers can shield edges from environmental damage like corrosion or impact. Proper storage also plays a crucial role—store tools in dry, organized spaces to prevent rust and accidental damage. Additionally, understanding equipment performance metrics can help you optimize operation and prolong lifespan. By staying proactive, you extend your equipment’s lifespan, improve performance, and avoid costly repairs caused by neglect.

Frequently Asked Questions

How Often Should I Perform Edge Inspections for Optimal Maintenance?

You should inspect your edges at least once a week for ideal maintenance. Regular checks help you catch early signs of wear or damage before they worsen. After heavy use or rough conditions, consider inspecting more frequently, such as every few days. Keep an eye on any cracks, chips, or uneven wear, and address issues promptly. Consistent inspections ensure your equipment stays in top shape and prevents costly repairs later.

Can Certain Environmental Conditions Accelerate Edge Wear?

Yes, certain environmental conditions can speed up edge wear. If you work in humid, salty, or abrasive environments, you’ll notice your edges degrade faster. High temperatures or frequent exposure to chemicals also accelerate wear and tear. To extend your equipment’s lifespan, you should regularly inspect and maintain edges, especially after exposure to these harsh conditions. Taking proactive steps helps prevent early damage and keeps your equipment performing efficiently.

What Are the Long-Term Effects of Ignoring Early Edge Damage?

Ignoring early edge damage can lead to progressive deterioration, causing your tools or equipment to become less precise and more prone to failure. Over time, small issues escalate into major repairs or replacements, increasing costs and downtime. You might also risk safety hazards if the damage affects structural integrity. To prevent these long-term problems, regularly inspect edges and address minor issues promptly, ensuring longevity and peak performance of your tools.

Are There Specific Industries More Prone to Edge Wear Issues?

Certain industries, like manufacturing, printing, and packaging, are more prone to edge wear issues because they handle high volumes of materials or operate equipment constantly. You’ll notice this in conveyor belts, cutting tools, or printing rollers wearing down faster. If you work in these sectors, regularly inspecting edges for signs of deterioration helps prevent costly downtime and equipment failure, keeping your operations running smoothly.

How Can I Differentiate Between Normal Wear and Early Signs of Failure?

You can tell if it’s early trouble or just normal wear by paying close attention. If you notice tiny cracks, unusual discoloration, or edges starting to chip, that’s a red flag. Normal wear usually looks like gradual, even thinning, not sudden damage. Trust your instincts—if something seems off, it’s better to check sooner than later. Catching small issues early can save you from major repairs down the line.

Conclusion

By regularly inspecting your equipment, you can catch early signs of edge wear before costly repairs are needed. Did you know that 70% of machinery failures are caused by overlooked wear and tear? Staying vigilant with simple checks and proactive maintenance can save you time and money. Don’t wait for visible damage—spotting trouble early keeps your tools running smoothly and extends their lifespan, ensuring you’re always one step ahead.